|

|

Post by lesorubcheek on Mar 7, 2008 13:17:45 GMT -5

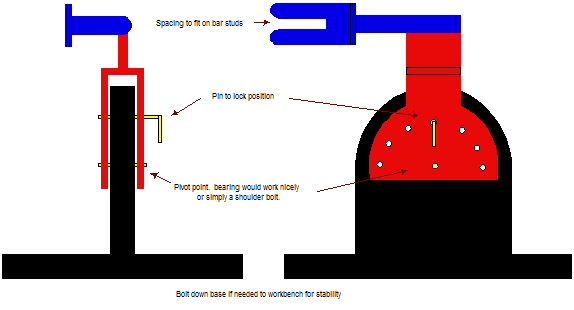

I was looking through an older issue of Chain Saw Age the other day and saw an article that really impressed me and thought I'd share. I'm sorry I can't remember the author's name, but he illustrated a simple stand for holding a saw on a workbench. I noticied that Efco used to make a really nice stand, but from this article, it looks simple enough to make a nice one youself. I sketched a quick outline showing the idea. Add some bearings at the pivot point and a notched locking pin, get rid of any sharp edges and it looks like it would be a handy thing to have around.  Dan |

|

|

|

Post by RBW on Mar 9, 2008 12:29:15 GMT -5

Excellent Idea Dan!!!

Not only will it be easier to work on, it will save your paint too.

.

|

|

|

|

Post by lesorubcheek on May 11, 2008 20:51:42 GMT -5

|

|

|

|

Post by hammerheadc4 on May 16, 2008 18:46:28 GMT -5

WoW..That is REAL nice!

|

|

|

|

Post by lesorubcheek on May 18, 2008 21:03:34 GMT -5

Thanks Hammerheadc4.... still waiting for time to put it to some use. Maybe soon.

Dan

|

|

|

|

Post by RBW on May 19, 2008 10:06:47 GMT -5

Looks like you did good Dan!

BTW, nice sewing machine! I actually know how to use one of those due to home ec classes in 7th grade. I had to show my wife how to work one and I still have to set it up for her.

|

|

|

|

Post by lesorubcheek on May 19, 2008 21:30:58 GMT -5

Thanks,

That's pretty cool you can sew! Can come in handy lots of the time. I can do some simple stuff, but nothing complex. My wife uses this machine to do free motion embroidery. She has an incredible gift... its amazing the things she can make with that machine.

Dan

|

|

|

|

Post by lesorubcheek on May 21, 2008 16:53:07 GMT -5

I finally tried it out a bit and it does really hold nicely. I think I'm gonna like it.   Dan |

|

|

|

Post by Trever on Nov 8, 2008 22:24:37 GMT -5

Dan,

You just had to show that 750! One of these days I'll own one of those great beasts.

Trever

|

|

|

|

Post by lesorubcheek on Nov 10, 2008 8:42:52 GMT -5

Dan, You just had to show that 750! One of these days I'll own one of those great beasts. Trever Yea Trevor, I just figured that would be the best saw to put on the stand to draw attention to it. I did put the worst one I had on there though tryin' not to show off or anything ;D. Dan |

|

|

|

Post by chainsawwhisperer on Nov 10, 2008 17:21:26 GMT -5

Every member WILL get a FREE 750 when they reach 500 posts.

RBW

|

|

|

|

Post by billg on Nov 10, 2008 20:42:18 GMT -5

Every member WILL get a FREE 750 when they reach 500 posts. RBW Well I'd better get busy. Bill |

|

|

|

Post by lesorubcheek on Nov 10, 2008 20:49:11 GMT -5

Woooo Hoooooo!!!

Dan

|

|

|

|

Post by sweepleader on Jul 3, 2013 19:07:51 GMT -5

|

|

|

|

Post by tommyhnavix on Jul 9, 2013 20:13:14 GMT -5

Nice job!! Nice design!!

Will have to make one!

Tom

|

|

|

|

Post by sweepleader on Jul 10, 2013 7:45:13 GMT -5

Thanks Tom.

The first design in the photos has pins to hold the sections from moving. I drilled the holes by hand and they were not well lined up requiring enlarging some of them. I guess I was impatient when building. I have since added large fender washers under the half inch bolts securing the sections. I bent the washers up to hold the bolt heads from turning and installed 10-32 socket head screws through the washer edge to prevent the washers turning. Now I hold the saw in the position desired with one hand and tighten the half inch bolt with a wrench in the other hand. It works much easier and is more stable as all the joints are tight, no play due to loose pins and no aligning pins while juggling the saw. I will post a picture of the new arrangement.

The half inch bolts could be secured from turning in a number of ways, I chose to do it one way without welding. It might be easier to drill a 1/4 inch hole in the bracket right next to the bolt head, insert a short 1/4 inch rod and weld it to the bolt. I may wind up welding the washer to the bolt or doing the rod thing, time will tell if my current method is robust.

I like this thing a lot, hope you do too.

|

|

|

|

Post by sweepleader on Jul 10, 2013 21:06:35 GMT -5

Here are a couple of pictures of the changes I made to the joints of the stand. I think it shows how the washer keeps the bolt from turning allowing the nut to be tightened with one hand on a wrench.   I didn't mention it before but there is a slotted spacer laying on the bench in the first photo of the other group of pics. It is to take the place of the clutch cover when working on that side of the engine. Of course a stack of washers would work but the spacer is a lot easier to use. |

|

|

|

Post by lesorubcheek on Jul 12, 2013 16:20:03 GMT -5

That's a great looking stand! These things can really help make a rebuild job go smoothly. It still surprizing there aren't more of these type things made and sold by companies like Oregon and such.

Dan

|

|

|

|

Post by sweepleader on Jul 12, 2013 17:45:19 GMT -5

Thanks Dan, yours was the inspiration. After seeing it there was no stopping me from having one. I thought that if I could get the same function without welding, more guys might be able to build something similar. I might still need to weld those bent washers, time will tell.

I suppose that if one were to build these for sale, of any design, it might be so expensive that not many would spring for it. On the other hand, it is hard to imagine someone working on saws for a living and not having one. As a former professional auto mechanic, good tools always seem cheap to me, no matter what they cost.

Thanks again for the idea,

Dan

|

|

|

|

Post by sweepleader on Jul 15, 2013 19:17:38 GMT -5

Ok, so time has told, I had to weld the washers to the bolt heads to keep them from turning. Otherwise it is working well. (Two more SXLAOs today, gotta get busy.) I don't have a good way to keep the bolts from turning without welding, maybe someone else will.

|

|